Low Dust

Low Attrition

High Crush Strength

Uniform Bead Size

High Adsorption Capacity

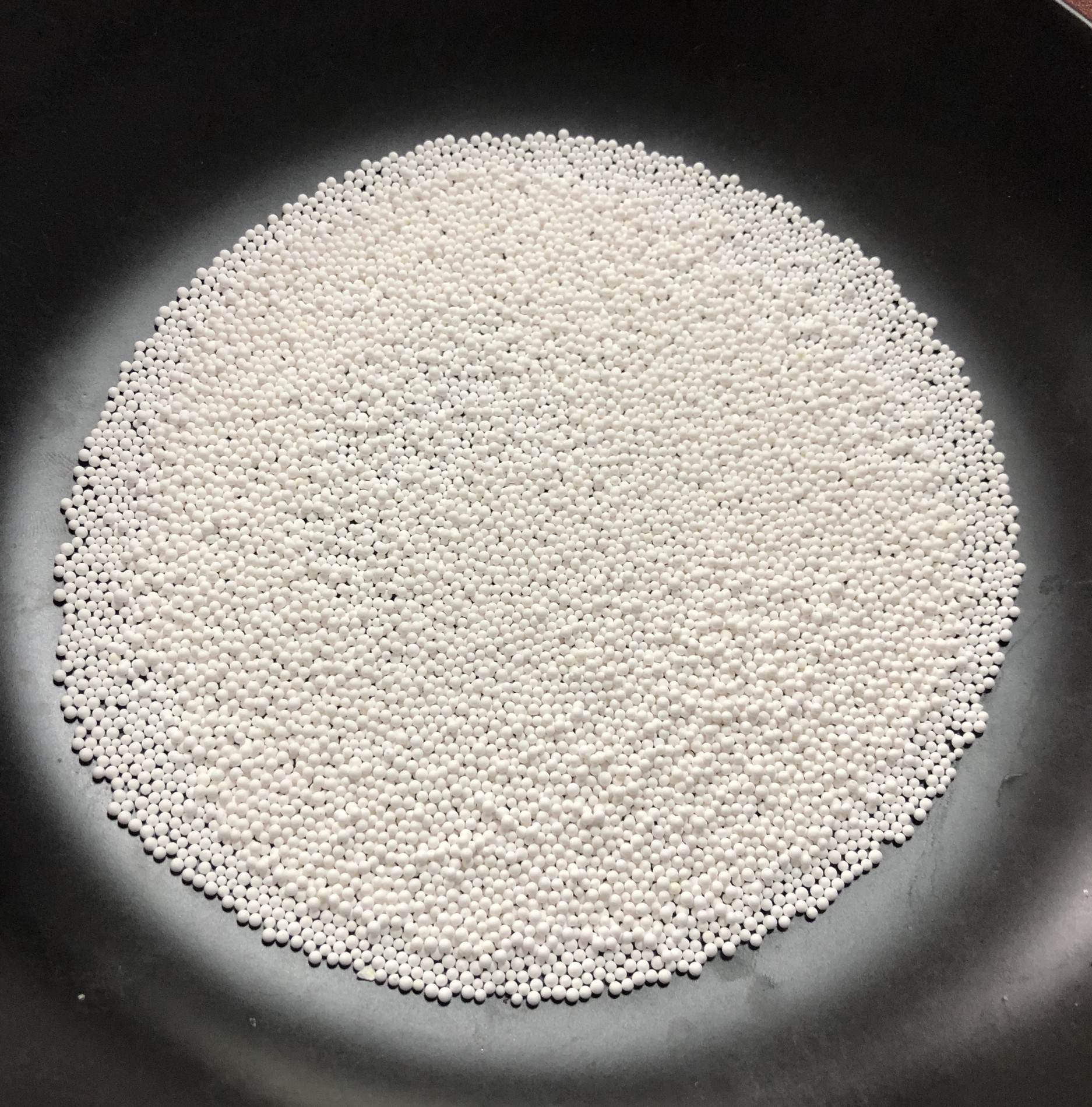

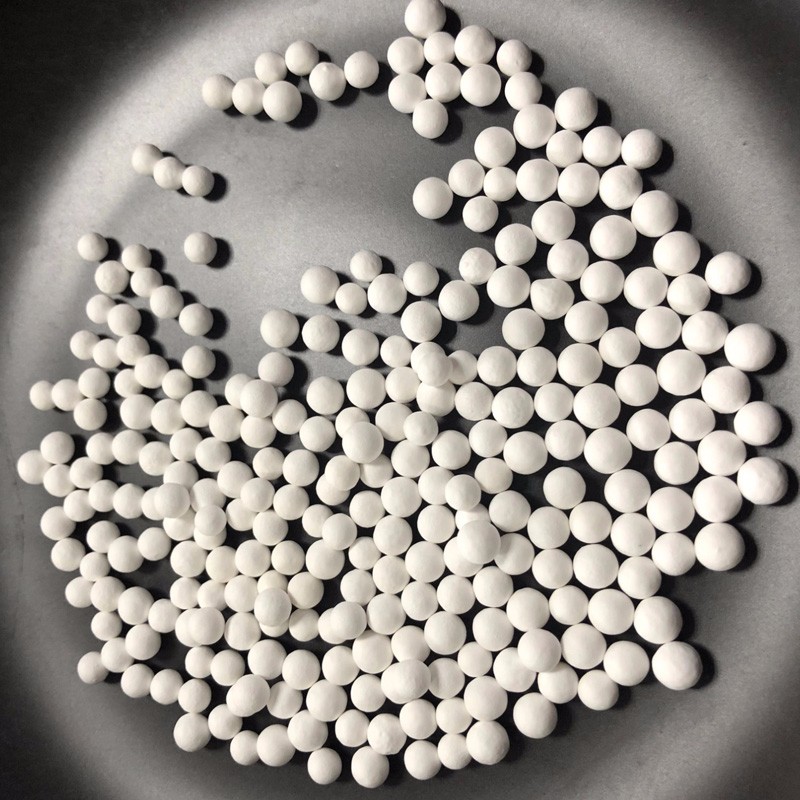

Activated Alumina Adsorbent in air separation (A-AS-A)

This line of products features high crush strengths and low dust content. The material is highly porous, can have a surface area greater than 330 m2/g, and can achieve dew points of -40°F to -100˚F, depending on operating conditions and the design of the dryer.

Features of activated alumina:

Low Dust

Low Attrition

High Crush Strength

Uniform Bead Size

High Adsorption Capacity

Activated alumina is often used in the following applications:

Compressed air drying

Natural gas drying

Removal of acids from transformer oils, lubricating oils, and refrigerant

Technical Property of Activated Alumina

| Type Item | A-AS-04 Absorbent | A-AS-DF Defluoridizer | A-AS-MS Absorbent for H2O2 | A-AS-AC Antichlor | A-AS-C Catalyst carrier | A-AS-A Absorbent in air separation | |||

| Appearance | White ball | ||||||||

| Main crystal phase | χ-ρ | χ-ρ | γ | χ-ρ | γ | χ-ρ | |||

Chemical composition % | Al2O3 | ≥93 | ≥93 | ≥92 | ≥90 | ≥93 | ≥90 | ||

| Na2O | ≤0.3 | ≤0.3 | ≤0.5 | 0.15-0.3 | ≤0.3 | ||||

| I.L | 6-8 | 6-8 | ≤8 | ≤ | ≤5 | 6-8 | |||

| Bulk density,g/ml | 0.68-0.72 | 0.70-0.75 | 0.65-0.75 | 0.68-0.78 | 0.70-0.80 | 0.68-0.72 | |||

| Surface area,m2/g | ≥280 | ≥280 | 200-260 | ≥300 | ≥200 | ≥300 | |||

| Pore volume,ml/g | 0.3-0.45 | 0.3-0.42 | 0.4-0.46 | 0.3-0.5 | 0.4 | 0.3-0.5 | |||

| Static absorption,% | Water 20 | Fluorin 0.12 | Water 50 | Chlorine 10-20 | Water 50-70 | Water 20 | |||

| Activity,% | - | - | 56-62 | - | - | - | |||

| Loss on abrasion,% | ≤1.0 | ≤1.0 | ≤1.0 | ≤0.7 | ≤0.4 | ≤0.8 | |||

| Crushing strength, N/grain | Φ1-2 | ≥40 | ≥40 | - | ≥40 | - | - | ||

| Φ2-3 | ≥60 | ≥60 | - | - | - | - | |||

| Φ3-5 | ≥100 | - | ≥100 | ≥82 | ≥100 | ≥100 | |||

| Φ4-6 | ≥120 | - | ≥130 | ≥120 | ≥120 | ≥110 | |||

| Φ5-7 | ≥120 | ≥150 | ≥150 | ≥150 | ≥160 | ≥150 | |||

| Φ6-8 | ≥200 | ≥200 | ≥200 | ≥200 | ≥220 | ≥200 | |||

The products in other types or sizes can also be manufactured if to the user's request.

Application

A-AS-04 activated alumina is manufactured from aluminium hydroxide by dehydroxylating it in a way that produces a highly porous material;

A-AS-DF activated alumina is also widely used to remove fluoride from drinking water. Basically, the more alumina in the filter, the less fluoride will be in the final, filtered water.

A-AS-MS is for absorbent H2O2

A-AS-AC is for chlorine absorbent

A-AS-C in hydrogen peroxide production, as a selective adsorbent for many chemicals including, in removal from gas streams .

A-AS-A activated alumina is used as a charge material in foreline traps to prevent generated by from backstreaming into the system

Industry standard HG/T39272007 Activated Alumina is issued by Zhengzhou Mahaco Industrial Co,Ltd